[CODE_4]: MEDIA_ELEMENT_ERROR: Format error

Piezas de repuesto gratuitas

Piezas de repuesto gratuitas

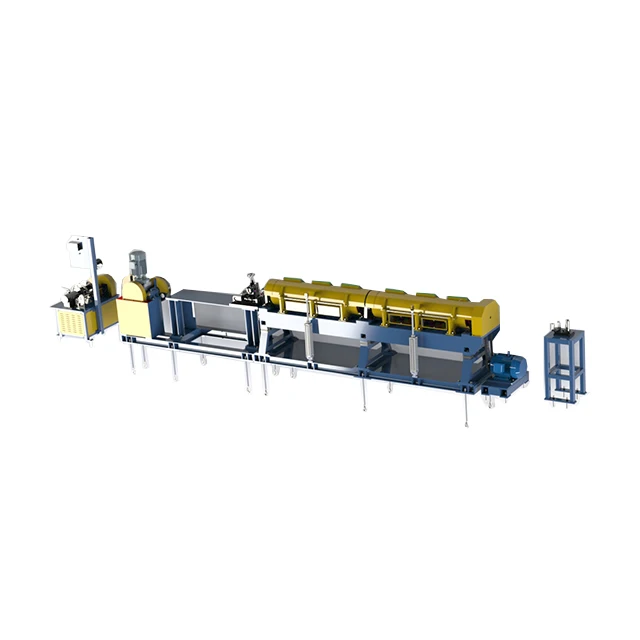

High Speed Wire Rope Steel Cable Making Tubular Stranding Machine

Tubular Stranding Machine

Application:

The high speed machines mainly used for stranding copper wire, aluminum wire, steel wire, ACSR and wire rope. Accompanied with taping head, it can used for insulation cores and some control cable stranding process.

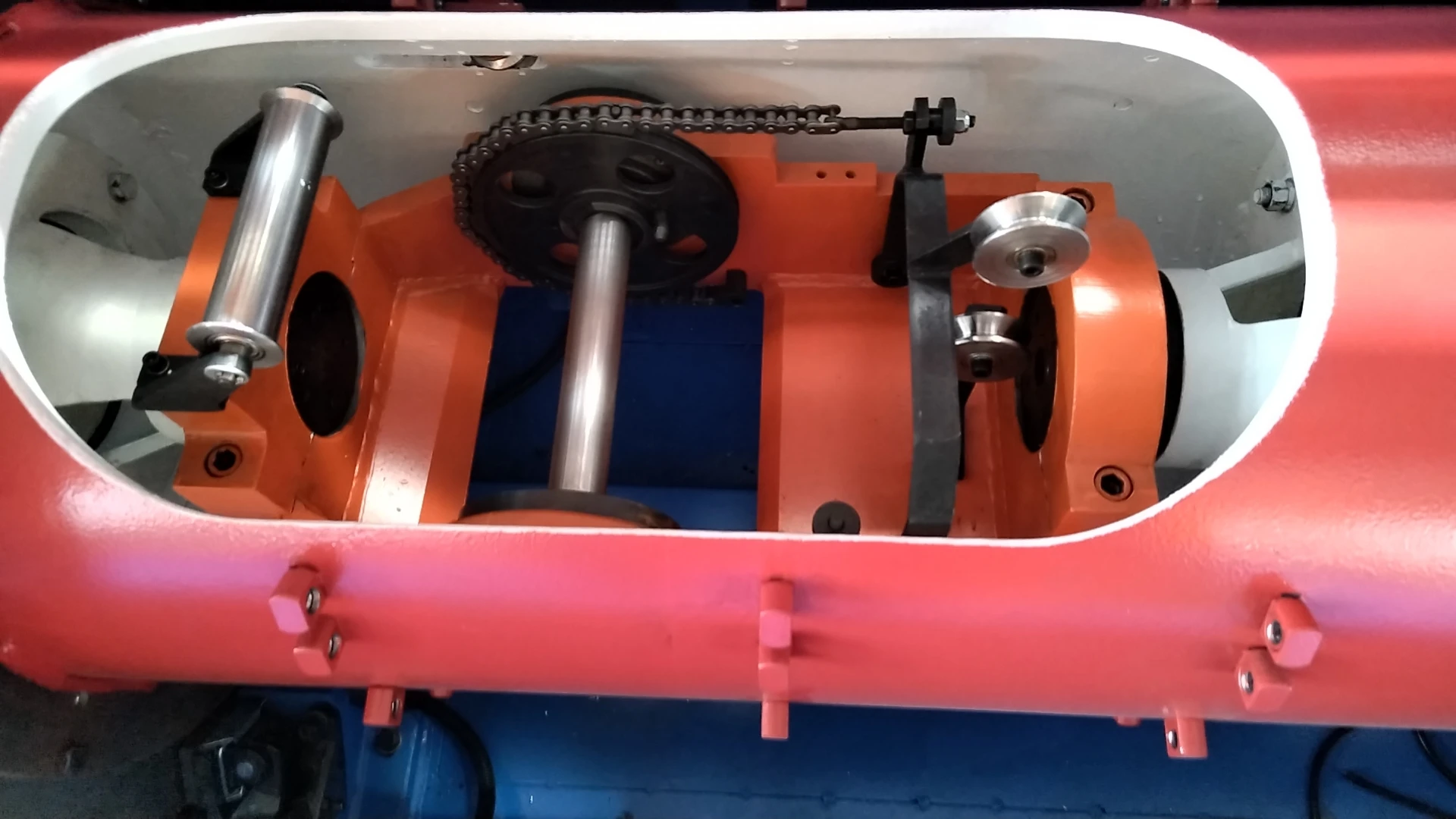

Component:

Central pay-off, cage host, taping device(optional), capstan, take-up and traverse device and electric control system.

Main Character:

1.The machine can work steadily with the whole holder, and the protect cover adopts high grade seamless steel tube, so the structure is also steady with lower noises.

2.The timing power can be manipulated easily to adjust the speed .The protect cover has the right and reverse direction circumrotate.

3. The main machine and the haul-off unit adopt shift gears case, so the working intensity is lower and the pitch is exact.

4. Equipped with automatic parking equipment -the safeguard, it means the machine will stop when the thread runs out or the door is open.

| Model | Wire Diameter[mm] | Rotating speed[rpm] | Traction Wheel Diameter[mm] |

| GJ-6/160 | 0.12-0.40 | 2200 | 2×250 |

| GJ-12/160 | 0.12-0.40 | 2100 | 2×250 |

| GJ-18/160 | 0.12-0.40 | 1900 | 2×250 |

| GJ-6/200 | 0.3-0.90 (strand 1.5) | 1600 | 2×320 |

| GJ-12/200 | 0.3-0.90 | 1500 | 2×320 |

| GJ-18/200 | 0.3-0.90 | 1400 | 2×320 |

| GJ-24/200 | 0.3-0.90 | 1300 | 2×400 |

| GJ30/200 | 0.3-0.90 | 1200 | 2×600 |

| GJ-36/200 | 0.3-0.90 | 1100 | 2×600 |

| GJ-6/250 | 0.4-1.0 (strand 1.5) | 1400 | 2×400 |

| GJ-12/250 | 0.4-1.0 | 1400 | 2×400 |

| GJ-18/250 | 0.4-1.0 | 1200 | 2×600 |

| GJ-24/250 | 0.4-1.0 | 1200 | 2×600 |

| GJ-30/250 | 0.4-1.0 | 1100 | 2×600 |

| GJ-36/250 | 0.4-1.0 | 1100 | 2×600 |

| GJ-6/300 | 0.5-1.3 (strand 2.0) | 1300 | 2×600 |

| GJ-12/300 | 0.5-1.3 | 1200 | 2×600 |

| GJ-18/300 | 0.5-1.3 | 1200 | 2×600 |

| GJ-24/300 | 0.5-1.3 | 1000 | 2×800 |

| GJ-30/300 | 0.5-1.3 | 1000 | 2×800 |

| GJ-36/300 | 0.5-1.3 | 900 | 2×800 |

| GJ-6/400 | 0.8-2.5 (strand 3.0) | 700 | 2×800 |

| GJ-12/400 | 0.8-2.5 | 700 | 2×1000 |

| GJ-18/400 | 0.8-2.5 | 600 | 2×1000 |

| GJ-24/400 | 0.8-2.5 | 600 | 2×1000 |

| GJ-30/400 | 0.8-2.5 | 600 | 2×1200 |

| GJ-36/400 | 0.8-2.5 | 600 | 2×1200 |

| GJ-40/400 | 0.8-2.5 | 600 | 2×1200 |

| GJ-6/500 | 1.0-3.5 (strand 5.0) | 650 | 2×1000 |

| GJ-12/500 | 1.0-3.5 | 650 | 2×1200 |

| GJ-18/500 | 1.0-3.5 | 500 | 2×1200 |

| GJ-24/500 | 1.0-3.5 | 500 | 2×1400 |

| GJ-30/500 | 1.0-3.5 | 500 | 2×1400 |

| GJ-36/500 | 1.0-3.5 | 500 | 2×1600 |

| GJ-40/500 | 1.0-3.5 | 500 | 2×1600 |

| GJ-48/500 | 1.0-3.5 | 500 | 2×1600 |

| GJ-6/630 | 1.5-5.0 (strand 7.0) | 500 | 2×1200 |

| GJ-8/630 | 1.5-5.0 | 450 | 2×1200 |

| GJ-12/630 | 1.5-5.0 | 450 | 2×1400 |

| GJ-18/630 | 1.5-5.0 | 400 | 2×1600 |

| GJ-24/630 | 1.5-5.0 | 400 | 2×1600 |

| GJ-30/630 | 1.5-5.0 | 400 | 2×1600 |

| GJ-36/630 | 1.5-5.0 | 400 | 2×1800 |

| GJ-40/630 | 1.5-5.0 | 400 | 2×1800 |

| GJ-48/630 | 1.5-5.0 | 400 | 2×1800 |

| GJ-6/800 | 2.0-6.0 (strand 11) | 400 | 2×1600 |

| GJ-8/800 | 2.0-6.0 (strand 11) | 400 | 2×1600 |

| GJ-12/800 | 2.0-6.0 | 350 | 2×1600 |

| GJ-18/800 | 2.0-6.0 | 350 | 2×1600 |

| GJ-24/800 | 2.0-6.0 | 300 | 2×1800 |

| GJ-30/800 | 2.0-6.0 | 300 | 2×1800 |

| GJ-36/800 | 2.0-6.0 | 300 | 2×2000 |

| GJ-40/800 | 2.0-6.0 | 300 | 2×2000 |

| GJ-48/800 | 2.0-6.0 | 300 | 2×2000 |

| GJ-6/1000 | strand 3.0-18.0 | 300 | 2×2000 |

| GJ-8/1000 | strand 3.0-18.0 | 300 | 2×2000 |

RONEN EQUIPMENT

On your side.

Ronen expertise can be found in the most varied

Fastener Equipment end products.

We reliably accompany you through everyday life. Mostly unnoticed.

After all, our precision-Fastener parts and Cold Forging

Technology are embedded into the products of our customers and, although not

always visible,they fulfil mission-critical functions there.

1.-Are you a manufacturer or trading company?

Cada pago que realices en Cooig.com está protegido con un estricto cifrado SSL y protocolos de protección de datos PCI DSS

Solicita un reembolso si tu pedido no se envía, falta o llega con problemas con el producto